Name

Innovative Application of Tunnel Grouting Material in Tunnel

Background

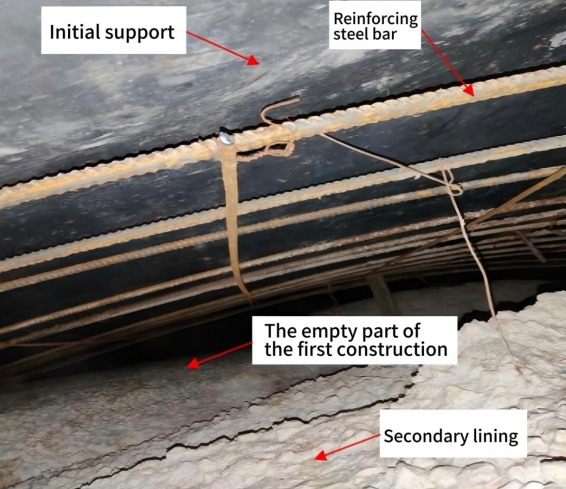

During the concrete pouring process of the tunnel secondary lining, issues such as insufficient pumping pressure, pipe blockages, and human judgment errors often lead to localized insufficient thickness at the vault and discontinuous concrete pouring. This results in quality defects such as falling blocks, water leakage, and cracking, which can cause serious accidents endangering traffic safety. Therefore, after the concrete pouring is completed, it is necessary to perform grouting to fill the voids at the vault.

Project challenge

Grouting backfilling includes two forms: conventional grouting and formwork grouting. Conventional grouting materials are prone to stratification, segregation, large shrinkage, and high water bleeding, making it difficult to ensure a good bond between the grout and the concrete. This leads to voids in the secondary lining, necessitating additional grouting. As a result, it not only increases construction costs but also adversely affects the quality control of secondary lining construction.

Solution from ARIT

ARIT has innovatively adopted the formwork grouting process to address the issue of tunnel voids. The main advantages of the formwork grouting process include two aspects: firstly, after the grouting is completed, the grouting material generates a slight volume expansion effect within the voids, and combined with the high grouting pressure, it ensures dense filling; secondly, the grouting material can effectively bond with the secondary lining concrete, forming an integrated structure that shares the load, thereby ensuring the mechanical performance and durability of the tunnel support structure.

Product from ARIT

For detailed remixing formula, feel free to connect technician of ARIT.

Address

22 Huixin Road, Nanjing, China

Call us

Email us

Connect with ARIT for Premium Concrete Admixtures