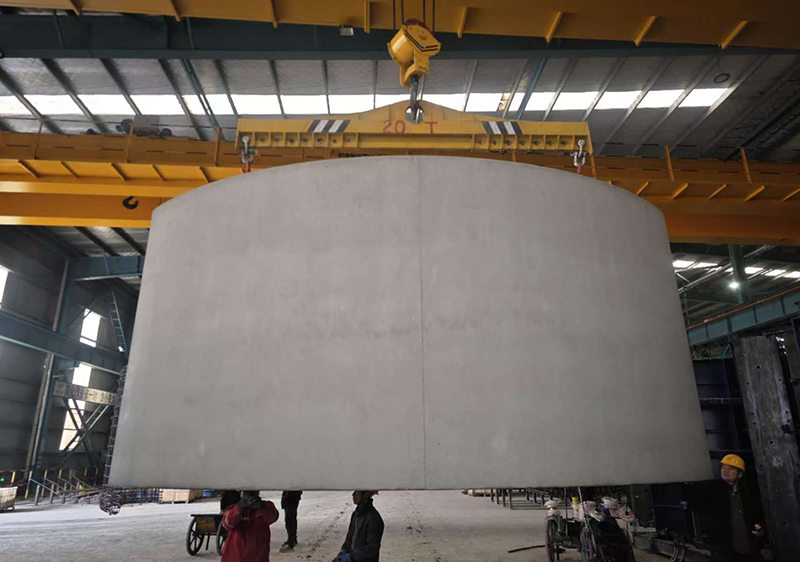

Project name:A Wind Tower Barrel Project In Tianjin

Background

This project is the first tower project undertaken by the client, the tower splicing height reaches more than 100 metres, the bottom diameter is about 6 metres, the concrete tower part needs to withstand the hub height of 150m, the impeller diameter of 204m of large wind power equipment. The customer has invested a lot in the production of supporting wind tower barrel by building an independent station and planning two production sites and a rebar tying area. Concrete design grade is C80, construction of individual specifications 2.5m * 0.15m * 360°/60°/45° (height * thickness * curvature). The construction is all cast in vertical moulds and shaped in one go, with a construction and curing temperature requirement of 20℃.

Project challenge

Surface bubbles, waterline problems, concrete laitance problems

Concrete appearance has more bubbles, water lines, after vibration appears thick laitance coating. The slump retention post-set return is large, the concrete viscosity is large, and there are leakage points in the four attached vibrators on each side of the site, as well as leakage phenomenon in manual vibration. In addition, the project requires that no thick laitance coating shall appear on the surface of the concrete after vibration, and no obvious bubbles and water lines on the surface of the tower after moulding.

Solution from ARIT

After adopting ART-M231 independently developed and produced by ARIT, the air bubbles on the surface of concrete are improved as a whole, the encapsulation of concrete is improved, and the slump retention time meets the requirements of on-site construction.

Product from ARIT

For detailed remixing formula, feel free to connect technician of ARIT.

Address

22 Huixin Road, Nanjing, China

Call us

Email us

Connect with ARIT for Premium Concrete Admixtures