Sustainable development is a widely known concept that has become increasingly important both now and in the future. Urban renewal needs infrastructure and construction, which generate a lot of carbon emissions. Concrete, regarded as the "most widely used man-made product on earth" and "the second most consumed substance on Earth after water," is one of the core foundational materials for construction, which include buildings, high-speed railways, subways, roads, airports, and so on.

China is the world's largest producer and consumer of concrete, and industries closely related to concrete, such as cement, sand and gravel aggregates, concrete admixtures, mineral mixtures, and concrete machinery equipment, all have production scales that rank first in the world. China started to develop low-carbon concrete in 2022 and is committed to achieving peak carbon emissions by 2030 and strive to achieve carbon neutrality by 2060.

"Carbon peak" and "carbon neutrality", collectively referred to as the "dual carbon" strategy, is a global strategic initiative aimed at addressing climate change by reducing carbon emissions.

As an important part of the building materials industry, the concrete industry is urgently seeking reasonable and effective measures for "carbon reduction and carbon emission reduction. The development of "low-carbon concrete" is the key to achieving the "dual carbon" goal.

Concrete admixture is closely correlated to the development of concrete. The emergence of concrete admixture is inherently linked to low-carbon and sustainable development. Firstly, the production of admixtures themselves can consume a large amount of industrial waste, meeting the demand for waste reuse and making the production of concrete more environmentally friendly. Secondly, admixtures improve the performance of concrete in a targeted manner, including concrete strength, durability, and fluidity, to meet the construction requirements of concrete. For instance, the application of early-strength water-reducing agents in the preparation of prefabricated concrete can enhance the development rate of early concrete strength, ensuring that the concrete meets the standard while saving energy by eliminating the need for steam curing. In addition, admixtures can promote the technological innovation and development of concrete according to changes in raw materials.

The production process, using room temperature and atmospheric pressure technology, adopts a advanced technology of DCS (Distributed Control System) automation control system, achieving automated control of batching, dripping, discharging, and metering, as well as full-process monitoring of reaction temperature. This reduces human operation errors, decreases labor intensity, improves production efficiency, and ensures product quality. The synthesis process has no need for external heat sources and generates almost no by-products, resulting in no emission of process-related waste.The main raw materials required are all common chemicals and are not toxic, explosive-making, or drug-making chemicals.The water used in the production process is mainly the circulating water produced by the heat exchange of cooling water in the reactor's internal coil, which is used for compounding, with no wastewater discharge.

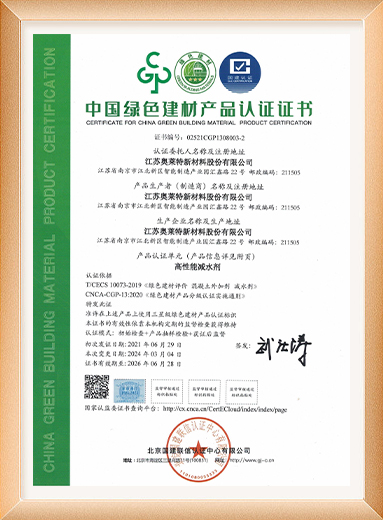

ARIT has been certificated as Chinese Green building material product since 2021, which prove green production process and green products.

R&D department starts to use industrial by-products as raw materials for our additives in order to reduce resource waste.

Based on lignin as the raw material. Lignin is a major byproduct of the cellulose industry, with the advantages of being a green and renewable resource, abundant in reserves, and containing a variety of active functional groups. Its modification can be used to prepare high performance water reducing agents with excellent properties.

Based on starch as the raw material. Starch is an extremely abundant natural organic carbohydrate in nature. Developing high-performance water-reducing agents from it is beneficial for alleviating the crisis of petrochemical resources, reducing carbon emissions, and achieving the greening, ecologicalization, and sustainability of admixture preparation.

Based on raw materials such as sulfates and aluminate. Sulfates and aluminate are common by-products in chemical production such as aluminum manufacturing. They can be used to prepare accelerators containing sulfates and aluminate, which significantly speed up the hardening of concrete. Take ART-SL15 and ART-SL37 for example, two products of ARIT flash setting admixture series, using aluminium sulphate as raw materials helps to improve setting time of concrete.

Based on slag as the raw material. Blast furnace slag from steel production is a common source of waste for preparing accelerators. After appropriate treatment, such as grinding into fine powder, these slags can serve as the main components of accelerators, helping to accelerate the hydration reaction of cement.

Based on phosphorus fertilizer waste as the raw material. Take ART-HQ310 and ART-HQ330 which are two powder flash setting admixture of ARIT for example. Phosphorus fertilizer waste occupies the main source of raw material, which effectively consume the waste and reducing costs have resulted in the product's excellent cost-performance ratio.

ARIT has Quality Management System Certification,Environmental Management System Certification, Occupational Health and Safety Management Certification which fulfil the requirements of the following standard: ISO 9001:2015, ISO 14001:2015, ISO 45001:2018.

These certifications fully demonstrate ARIT’s efforts in sustainable development and that ARIT’s management level is gradually reaching international standards. ARIT is committed to high-quality product quality management, care about environmental protection issues, and strive to create a healthy and good workplace environment for our employees.

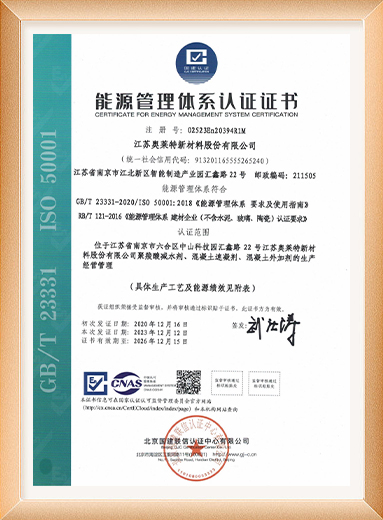

ARIT has also certificated for Energy Management System Certification which meets the standard of ISO 50001:2018, which proves that ARIT has established the concept of energy saving and emission reduction and has formed a self-discipline mechanism for energy conservation and emission reduction.

Effective ways to reduce the amount of cement include using alternatives and optimizing mix design which all require the use of admixture.

Incorporating alternative materials such as fly ash, slag, or silica fume as cement replacements or recycled materials such as crushed concrete aggregate or other solid waste can reduce the overall new cement content in concrete mixes. Proper mix design would be adjusted continuously when materials change. High performance admixtures and advanced technologies will be inevitable to achieve the desired strength and workability with the least amount of cement while maintaining performance.

The ability to adjustment of admixture formula is core competitiveness of ARIT. ARIT excels at providing customers with mix design optimization of concrete to meet the performance requirements of actual engineering projects and all products have strong compatibility with different materials.

The continuous change of materials, the customization and multi-functionality of admixture, and the professional technical service personnel are becoming trends.

The durability of concrete is an important aspect of its sustainability. Adding various admixtures to concrete can enhance its ability to resist various environmental influences and load conditions, thereby extending its service life.

Water reducing admixture. Such as ART-M611 and ART-M417 ARIT offer. By reducing the amount of water used and lowering the water cement ratio, they improve the compactness, permeability resistance, and erosion resistance of concrete.

Air entraining agents. By forming a uniform distribution of tiny air bubbles in the concrete, they improve the concrete's resistance to freeze-thaw cycles. These tiny air bubbles can absorb the pressure generated by the expansion of freezing water, preventing the formation of cracks, thereby enhancing durability in cold environments.

Retarding agents and accelerating agents. By adjusting the setting time of concrete, they prevent the concrete from hardening too quickly or too slowly, reduce hydration defects, and improve durability.

Flash setting admixture. In spraying concrte, if the concrete does not set and gain sufficient strength rapidly, it can lead to excessive rebound, where a significant amount of the material falls off the formwork or surface, making it unusable and discarded as waste.This not only wastes materials but also increases construction time and costs. Take ART-SL15, high strength alkali-free liquid accelerator of ARIT for example. ART-SL15 shows good long-term strength development, reducing dust and rebound rate and lowering the risk of alkali-aggregate reaction which are helpful to concrete durability.

Waterproofing agents. They enhance the water resistance of concrete, reducing the permeation of water and other harmful solutions, thus improving the waterproofing capability of the concrete.

Anti-corrosive agents. By forming a protective layer, they shield the steel reinforcement within the concrete from corrosion in chloride-rich environments, extending the service life of reinforced concrete structures.

Proper use of these admixtures ensures that the concrete sets at an optimal rate, maintaining both the quality and efficiency of the construction process.

Superplasticizers represent the most widely used type of admixture. Right now more than 75% of the admixtures used in China are superplasticizers. Water reducing improves both the strength and durability of concrete, both of which can be leveraged to make more sustainable concrete, therefore increasing the greater use of superplasticizers in order to advance sustainability.

ARIT will intensify research and development efforts, focusing on the technology of "low-carbon concrete" admixtures and utilizing more green raw materials and green synthesis techniques to prepare high performance admixture.

ARIT pays close attention to environmental protection and human health, contributing strength to the sustainable development of the world.

Address

22 Huixin Road, Nanjing, China

Call us

Email us

Connect with ARIT for Premium Concrete Admixtures