Product first-time acceptance rate is 100%

Customer satisfaction ≥ 98%.

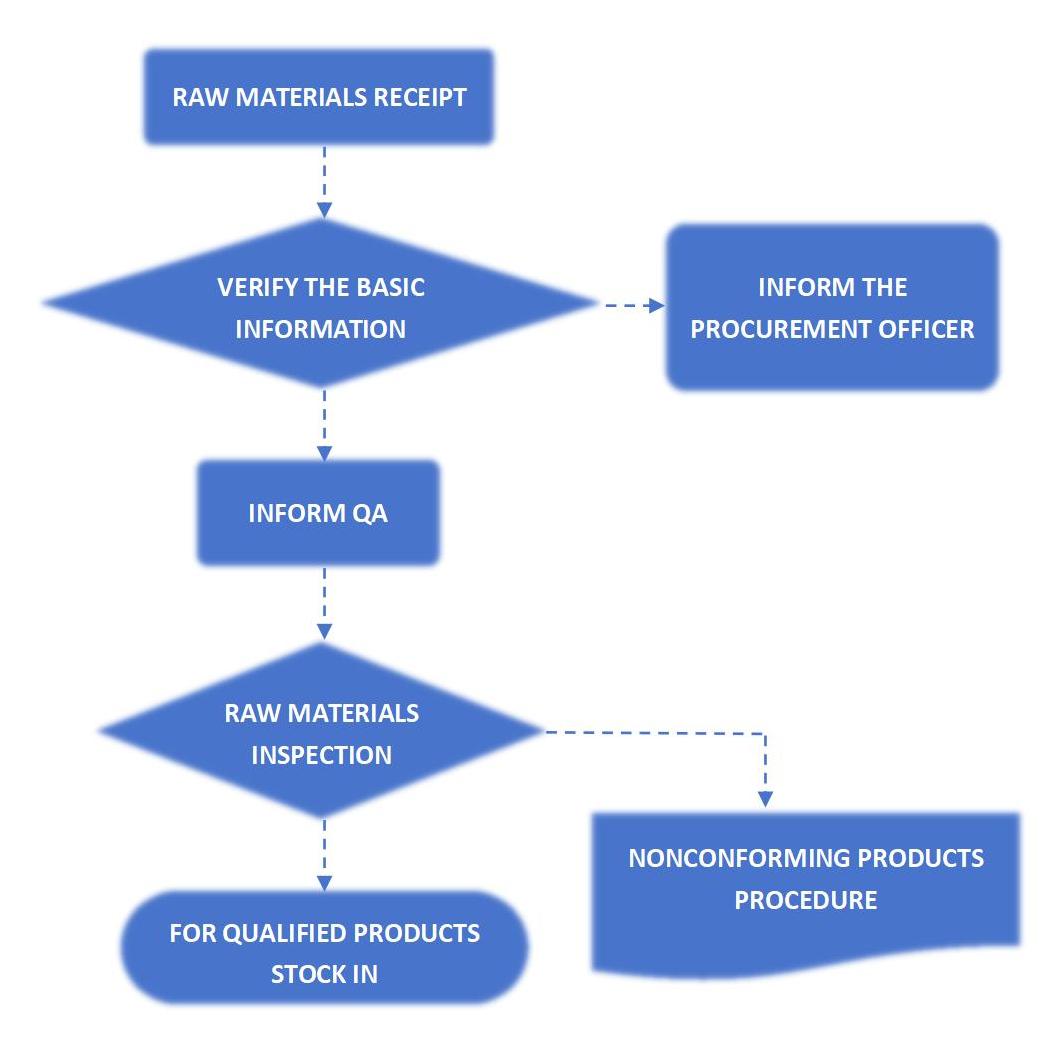

SCM(supply chain management) places orders for raw materials. When raw materials are transported to the factory, warehouse keeper will check for the basic information first. Then warehouse keeper will inform purchaser and quality control department. QA(quality assurance) will inspect the performance for raw material. For conforming goods, raw materials will be stock in and preserved. For nonconforming products, SCM will execute the return procedure.

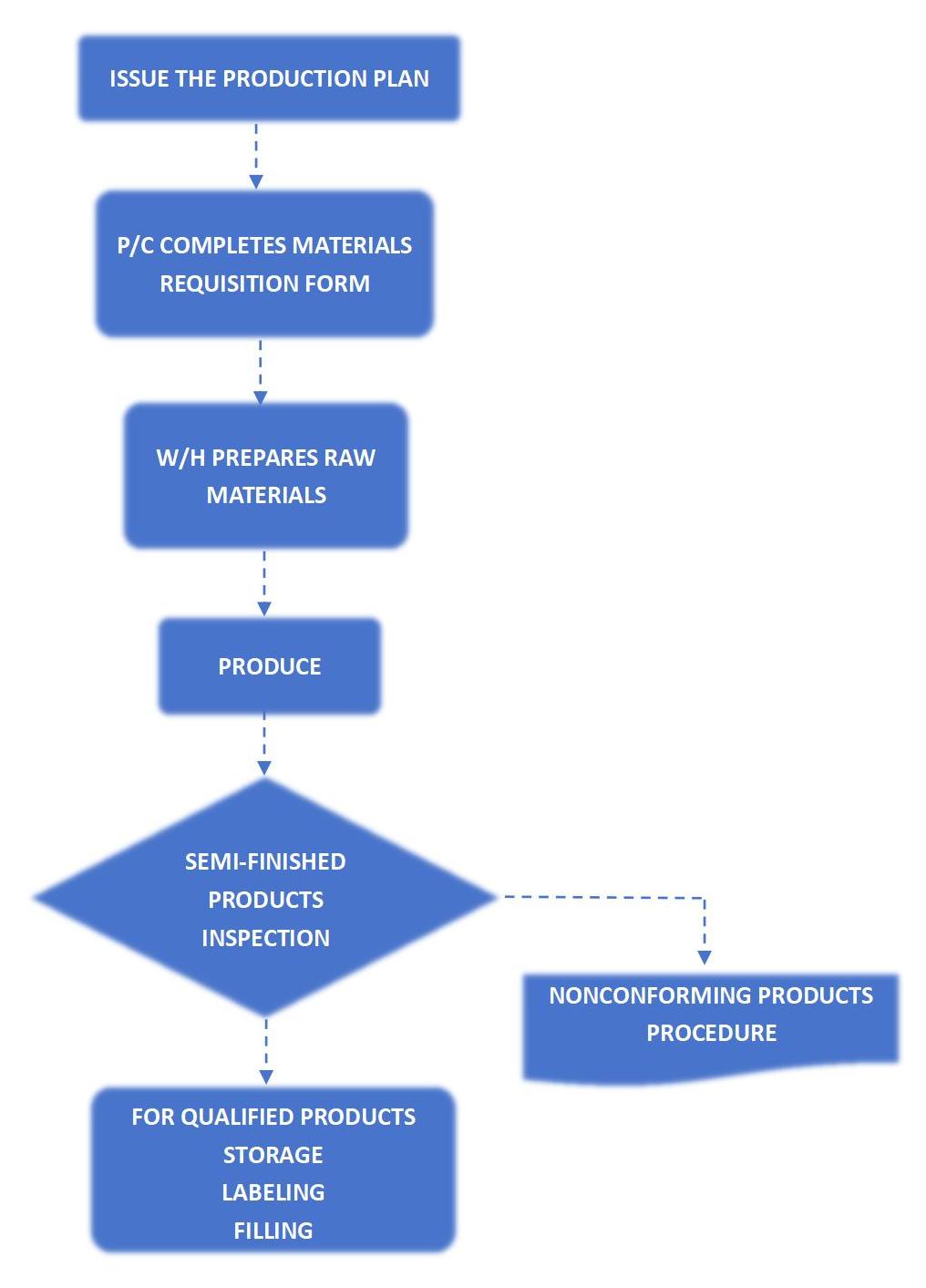

Sales submit a goods requisition form online. SCM team will distribute the manufacturing schedule. The production center(P/C) fills out a material requisition form and W/H(warehouse) will verify the form and prepare the raw materials. Raw materials will react at different reactors and after reacting one bottle of 500 ml sample at each reactor will be sent to quality control department. QA(quality assurance) will inspect the performance for semi-finished products. For conforming goods, semi-finished products will be stored and filled into inventory tanks. For nonconforming products, SCM will execute the nonconforming products procedure.

Semi-finished products will be compounded in the blending workshop. After each batch is compounded, a sample will be set aside for testing at the Quality Center. Once the performance requirements are met, a Quality Guarantee Certificate and a Certificate of Conformity will be provided, and then the products will be loaded onto vehicles for shipment from the factory.

ARIT has Quality Management System Certification which fulfills the requirements of the standard of ISO 9001:2015.

Address

22 Huixin Road, Nanjing, China

Call us

Email us

Connect with ARIT for Premium Concrete Admixtures